Laminated Veneer Lumber (LVL) timber is a popular choice for formwork in construction projects. Its strength and durability make it ideal for supporting concrete structures during the pouring and curing stages. However, not all LVL timber is created equal, and choosing the best option for your formwork needs requires careful consideration. In this article, we will explore the key factors to consider when selecting LVL timber for formwork, as well as tips for evaluating timber suppliers and maintaining and caring for LVL timber formwork.

Understanding LVL Timber

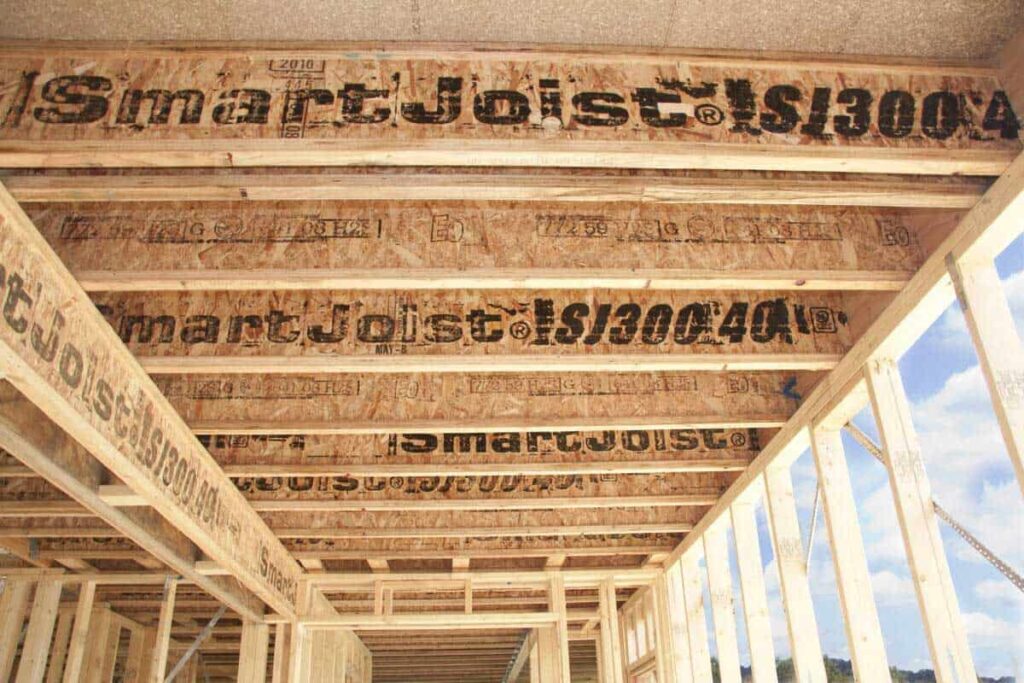

Before delving into the selection process, it’s important to have a clear understanding of what LVL timber is. LVL is made by bonding thin veneers of wood together with adhesive to create a strong and uniform material. It is known for its high strength-to-weight ratio and dimensional stability, making it a reliable choice for formwork.

In conclusion, choosing the best LVL timber formwork involves considering factors such as timber quality and strength, size and dimensions, and the environmental impact of production. Evaluating timber suppliers based on reputation, certifications, and customer service is also crucial. Finally, proper maintenance and care practices such as storing timber correctly, regular inspection and repair, and safe disposal and recycling should be implemented to maximize the lifespan and performance of LVL timber formwork. By following these guidelines, you can ensure that you select the optimal LVL timber for your formwork needs, leading to successful and reliable construction projects.

What is LVL Timber?

Laminated Veneer Lumber, or LVL, is a type of engineered wood made from thin layers of wood veneers. These veneers are bonded together with adhesives under high temperature and pressure, resulting in a strong and durable product. LVL timber can be manufactured from a variety of wood species, including pine, spruce, and eucalyptus.

One of the key advantages of LVL timber is its versatility in construction applications. It is commonly used in beams, headers, and studs, providing structural support in residential and commercial buildings. The manufacturing process of LVL allows for customization in terms of thickness, width, and length, making it a flexible choice for various project requirements.

Benefits of Using LVL Timber for Formwork

There are several benefits to using LVL timber for formwork. Firstly, its high strength allows it to support heavy loads and withstand the pressures of concrete pouring and curing. Additionally, LVL timber is dimensionally stable, meaning it is less prone to warping and twisting compared to solid timber. This stability ensures that the formwork maintains its shape and helps prevent concrete deformations.

Moreover, LVL timber is environmentally friendly as it is made from sustainable wood sources. By using LVL in construction projects, builders can contribute to reducing the demand for solid timber from old-growth forests. This sustainable approach aligns with the growing trend towards eco-friendly building materials and practices in the construction industry.

Factors to Consider When Choosing LVL Timber

Now that we have a basic understanding of LVL timber, let’s discuss the key factors to consider when choosing the best option for your formwork needs.

When it comes to selecting LVL timber for your construction projects, there are several additional factors to keep in mind to ensure the best results. Understanding these factors can help you make informed decisions that will contribute to the success and longevity of your structures.

Read more at: Comparing LVL Formwork vs. Traditional Timber

Timber Quality and Strength

The quality and strength of the LVL timber are crucial factors to consider. Look for timber that meets industry standards and has a high strength rating. It’s also important to consider the manufacturing process. Choose LVL timber that has been properly kiln dried to reduce moisture content and enhance its strength and stability.

Additionally, consider the specific grade of the timber as different grades offer varying levels of strength and durability. Opting for a higher grade of LVL timber may result in a more robust and long-lasting formwork solution, especially for projects with demanding structural requirements.

Timber Size and Dimensions

The size and dimensions of the LVL timber will depend on the specific requirements of your formwork project. Ensure that the timber you choose is of the appropriate size and thickness to support the loads and dimensions of your construction project. You may need to consult with a structural engineer or formwork specialist to determine the right specifications.

Moreover, consider the potential for customization when selecting LVL timber. Some suppliers offer tailored cutting services that can provide you with timber pieces precisely sized and shaped to fit your project’s unique needs, saving time and effort during construction.

Environmental Impact of Timber Production

If sustainability is important to you, consider the environmental impact of timber production. Look for LVL timber that is sourced from responsibly managed forests and carries certification from organizations such as the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI). These certifications ensure that the timber is harvested in an environmentally friendly and sustainable manner. Find more about sustainable on https://sustainability.psu.edu/about-us/what-is-sustainability/

Furthermore, explore the possibility of utilizing reclaimed or recycled LVL timber for your formwork needs. By opting for recycled timber, you can reduce the demand for new timber production and contribute to the conservation of natural resources, making a positive impact on the environment through your construction choices.

Evaluating Timber Suppliers

Once you have identified the key factors to consider when choosing LVL timber for formwork, it’s time to evaluate timber suppliers. Selecting a reputable and reliable supplier is crucial to ensure the quality and consistency of the timber you receive.

When it comes to evaluating timber suppliers, there are several additional factors to take into consideration to make an informed decision. Understanding the sourcing practices of the supplier can provide valuable insight into the sustainability and environmental impact of the timber you are purchasing. Suppliers who prioritize responsible forestry practices and have certifications like FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) demonstrate a commitment to ethical sourcing.

Reputation and Reviews

Start by researching and assessing the reputation of potential timber suppliers. Look for suppliers with positive reviews and a track record of supplying high-quality LVL timber to construction projects. Seek recommendations from colleagues or industry professionals who have experience working with LVL timber for formwork.

Additionally, consider the longevity of the supplier in the industry. A supplier with years of experience and a proven track record is more likely to have established reliable processes for timber production and delivery, ensuring consistency and quality in their products.

Certifications and Standards

When evaluating timber suppliers, consider whether they hold relevant certifications and adhere to industry standards. Suppliers who have certifications such as ISO 9001 or comply with the AS/NZS 4357 Standard for LVL timber production are more likely to provide consistent and reliable products. To learn more about click here.

Customer Service and Support

Customer service and support are crucial when working with timber suppliers. Consider whether the supplier provides assistance with product selection, technical advice, and support throughout the ordering and delivery process. A supplier who can offer prompt and reliable customer service will help ensure a smooth and successful formwork project.

Maintenance and Care for LVL Timber Formwork

Finally, to maximize the lifespan and performance of your LVL timber formwork, it’s essential to implement proper maintenance and care practices.

Proper Storage of LVL Timber

When not in use, store LVL timber in a dry and well-ventilated area to prevent moisture absorption and minimize the risk of fungal growth or decay. Stack the timber on a level surface and, if possible, elevate it slightly off the ground to avoid direct contact with moisture.

Regular Inspection and Repair

Regularly inspect your LVL timber formwork for any signs of damage or wear. Check for cracks, splits, or excessive deformation that may compromise the structural integrity of the formwork. Repair or replace damaged sections promptly to ensure safe and reliable formwork during construction.

Safe Disposal and Recycling of LVL Timber

At the end of its useful life, it’s important to dispose of LVL timber responsibly. Explore recycling options and ensure that any waste timber is sent to appropriate recycling centers or facilities. Recycling LVL timber helps reduce waste and supports sustainable practices in the construction industry.

Additionally, when storing LVL timber, it is crucial to consider the surrounding environment. Avoid storing the timber near sources of excessive heat or direct sunlight, as this can lead to warping or drying out of the wood. Similarly, keep the timber away from chemicals or corrosive substances that could damage the material.

Furthermore, during the regular inspection of your LVL timber formwork, pay close attention to the connections and joints. Over time, these areas may experience wear and tear, leading to loosening or instability. By identifying and addressing these issues early on, you can prevent potential accidents or structural failures during construction.

Moreover, when disposing of LVL timber, it is important to follow local regulations and guidelines. Some areas may have specific requirements for the disposal of construction materials, including timber. By adhering to these regulations, you can contribute to a cleaner and more sustainable construction industry.